Reliable Ammonia Catalyst Solution

Home / All

Ammonia Synthesis Catalysts Manufacturer

23 results

ViewShowcase

Pre-reforming catalyst is a high Ni system supported on a porous carrier.

Enhance your ammonia synthesis gas production with SYAMCAT's Primary Steam Reforming Catalyst.

ZnO Desulfuration Catalyst has deep desulfurization extent, easy to use and high sulfur capacity.

ZnO Desulfuration Catalyst has deep desulfurization extent, easy to use and high sulfur capacity.

Hydrogenation catalyst for hydrogen production with cobalt molybdenum nickel ternary active components.

Hydrogenation catalyst for hydrogen production with cobalt molybdenum nickel ternary active components.

SYAMCAT TH18 is a high efficient catalyst to use Pt or Pd precious metal as main active component.

SYAMCAT B317 is an energy efficient catalyst made by precipitation process.

The iron-molybdenum formaldehyde catalyst is primarily used in the methanol-to-formaldehyde oxidation process via the iron-molybdenum method.

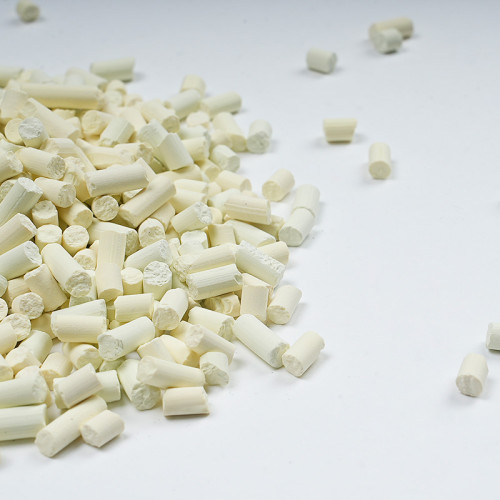

Ammonia synthesis catalyst is divided into oxidation and reduction state to serve our excellent customers.

ZnO Desulfuration Catalyst has deep desulfurization extent, easy to use and high sulfur capacity.

Ammonia synthesis catalyst is divided into oxidation and reduction state to serve our excellent customers.

Enhance your ammonia synthesis gas production with SYAMCAT's Primary Steam Reforming Catalyst.

Hydrogenation catalyst for hydrogen production with cobalt molybdenum nickel ternary active components.

Enhance your reformer's performance with SYAMCAT's Secondary Steam Reforming Catalyst.

Secondary steam reforming catalyst has good activity, heat resistance, and structural stability.

Pre-reforming catalyst is a high Ni system supported on a porous carrier.

Methanol synthesis catalyst with alumina as carrier and copper as active component.

Methanation Catalyst with Long Service Life for Methanation Process.

Low temperature shift catalyst is taking copper oxide as active component, zinc oxide as structure promoter.

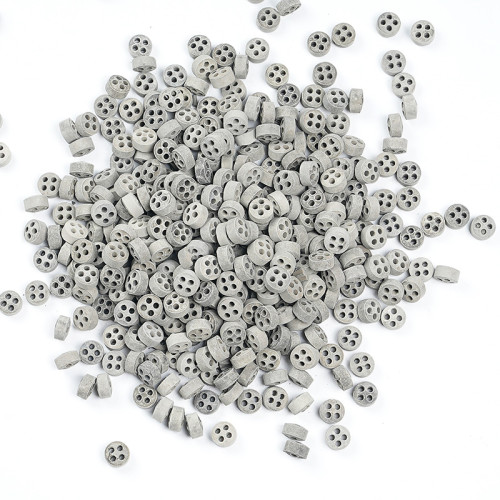

High temperature shift catalyst is taking iron oxide as active component, chromic oxide as structure modifier.

Elevate your ammonia plant's efficiency with SYAMCAT's Primary Steam Reforming Catalyst.

Please send your message to us

SYAMCAT is a professional manufacturer of synthetic ammonia catalysts with over 30 years of catalyst experience and history,Through continuous technological innovation, we offer catalyst solutions for ammonia production.If you would like to learn more or are in search of a manufacturer for synthetic ammonia catalysts for your company, please feel free to contact us.

- Mobile Phone

- *Title

- *Content

subscription