Improving Methane Steam Reforming Catalyst Stability with SYAMCAT

Improving Methane Steam Reforming Catalyst Stability with SYAMCAT

Stability is a crucial factor in catalyst performance. In methane steam reforming reactions, catalyst deactivation primarily occurs due to three factors: poisoning deactivation, coking deactivation, and sintering deactivation.

Addressing Poisoning Deactivation

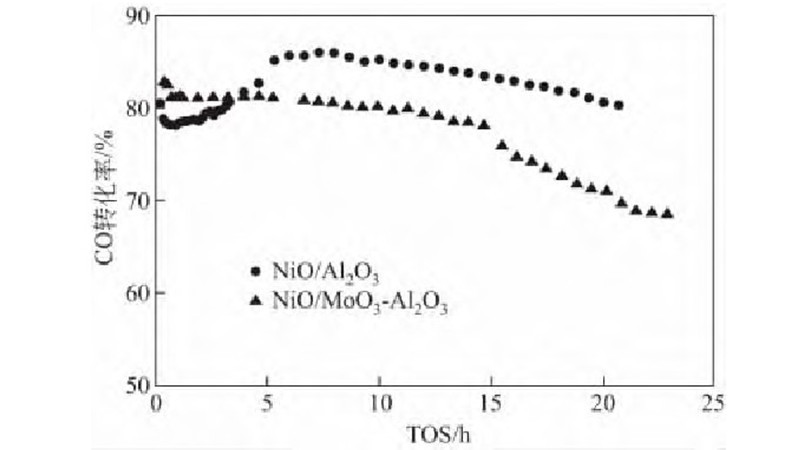

Nickel-based catalysts are the most commonly used catalysts in methane steam reforming reactions. These catalysts are susceptible to poisoning, with compounds like sulfur, chlorine, and arsenic being common poisons, such as H2S and SO2 in methane gas. Sulfur's unshared electron pairs can form coordination bonds with nickel's s orbitals, occupying the active surface sites of nickel and causing catalyst deactivation. Currently, the addition of promoters can improve the sulfur resistance of nickel-based catalysts. Studies by Luo Laitao and Tian Dayong respectively found that adding samarium and molybdenum can increase the electronegativity of the nickel surface,

hindering sulfur adsorption and thereby enhancing catalyst sulfur resistance, ultimately improving catalyst stability.

Mitigating Coking Deactivation

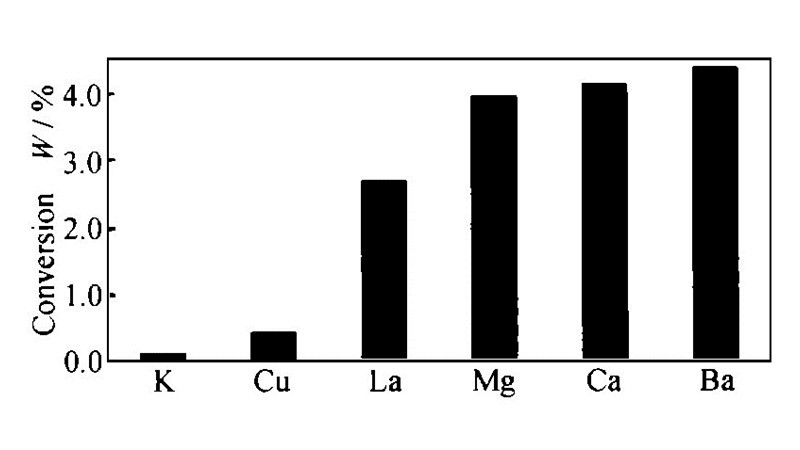

Methane steam reforming reactions involve side reactions such as CO disproportionation and CH4 cracking, which can lead to coke formation. Coke formation can block active sites and pore channels, reducing catalyst activity. The addition of promoters can also enhance the catalyst's resistance to coking. Qian Ling introduced various metals

such as K, Mg, and Ca as promoters into Ni/γ-Al2O3 catalysts. The results showed that each promoter improved the catalyst's resistance to coking, especially K, which reduced the coke content on the catalyst surface to 0.1%.

Enhancing Catalyst Resistance to Coke Formation

Liu Zhongkan studied the resistance to coking of Ni-based catalysts with rare earth additives using temperature-programmed surface cracking and reduction methods. It was found that in catalysts with rare earth additives, reducing nickel particle size is advantageous for increasing the CH4 cracking reaction rate and water adsorption

capacity. Since CH4 is adsorbed on active centers, more water molecules react with it, resulting in an increased actual water-to-carbon ratio and accelerated reaction rates of carbon with water, making it less likely for the cracked carbon to deposit.

Strategies Against Sintering Deactivation

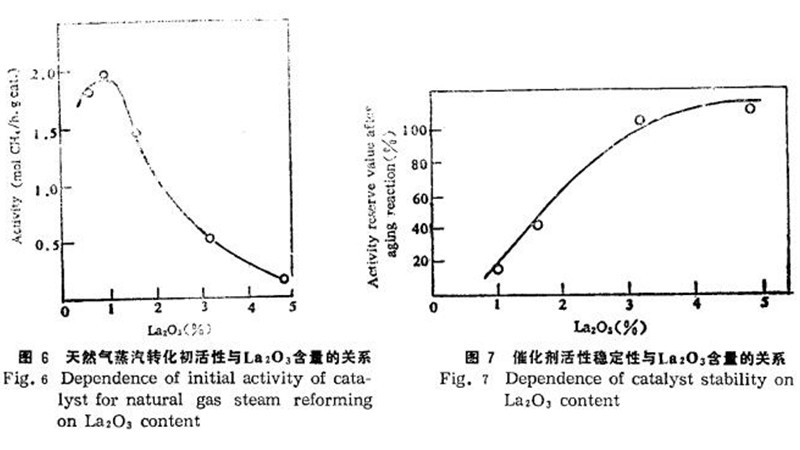

Additionally, there is sintering deactivation, where atoms or nanoparticles migrate on the carrier surface under certain conditions and aggregate into larger particles, leading to sintering and a reduction in active catalyst sites. Improving the carrier and active component properties can enhance sintering resistance. Hu Zeshan found that

lanthanum can form barriers around nickel, hindering its migration and growth to resist sintering. Zhang Cheng found that Cr2O3 acts as a thermal barrier in catalysts, effectively inhibiting Ni grain growth, thereby enhancing catalyst thermal stability.

Introduction to SYAMCAT Solutions

At the end of the article, it's worth mentioning SYAMCAT and the SYAMCAT Steam Reforming Catalyst to guide potential clients to inquire about our products.

For ammonia indusries seeking advanced solutions in catalyst development and optimization, SYAMCAT offers cutting-edge technologies to enhance catalyst performance and stability. Our expertise extends to various catalytic processes, including methane steam reforming.

The SYAMCAT Steam Reforming Catalyst is engineered to deliver superior performance and durability in methane steam reforming applications. With our innovative formulations and precise engineering, SYAMCAT catalysts offer enhanced resistance to poisoning, coking, and sintering, ensuring prolonged catalyst lifespan and optimal process efficiency.

For further inquiries or to explore how SYAMCAT can elevate your catalyst requirements, please contact us for personalized consultation and solutions tailored to your specific needs.